Arnav Prasad

Practices robotics, mechanical design, programming, and educating.

Senior Design: A Fine Powder Transport System

Group Project for MEEG304 at the University of Delaware, Sponsored by QFix

Background and Problem Statement

QFix is a medical device company located in Avondale, PA. They focus on the design and manufacture of patient positioning systems, used to keep patients comfortable and still during radiation therapy procedures. One type of product they make is a thermoplastic mask, which is form-fitted to the patient's head.

The thermoplastic masks are created from a combination of polymers, including a unique additive "yellow powder" (which was not named or specified to keep QFix's IP protected). This yellow powder must be introduced to the mixing system through a hopper located 9 feet above the manufacturing floor. Before the project, the hopper was refilled manually - every 15 minutes, an employee will climb up a ladder with a drum of powder and a hand scoop, and top off the hopper. QFix was looking for a solution where they could empty an entire 25kg drum of yellow powder at once, and keep the hopper full automatically. Additionally, having the loading process closer to the manufacturing floor would be safer and easier.

Constraints and Targets

| Constraint | Target Value |

|---|---|

| Powder availabile in hopper | ≥ 72g at all times |

| Ergonomics & Safety | Adhere to OSHA 1910.212 and NIOSH lifting recommendation of < 51lb |

| Device Size | Max footprint: 123" x 78" Reach: 8'8" above floor |

| System compatibility | System must be able to be retrofitted to existing machinery System must accommodate 25kg powder drum |

| Cost | < $15,000 for automated powder transport system < $1,500 for subcomponents. |

Wants and Targets

| Want | Target Value |

|---|---|

| Powder utilization | < 1% of each drum (250g) lost to spillage / dead volume |

| Mobility & Ease of Use | Only 1 employee required to operate the loading system |

Substitute Powder

As stated earlier, QFix was understandably protective of their yellow powder additive, for IP security. For our testing, we were tasked with finding a suitable proxy material, which had similar properties to the additive powder. QFix provided us with the relevant properties of the powder, and this table summarizes our options when looking at alternatives.

| Material | Density (g/ML) | Bulk Density (g/ML) | Particle Diameter (μm) |

|---|---|---|---|

| QFix "Yellow Powder" | 0.8 | 0.4-0.5 | 100-150 |

| Polystyrene Microspheres | 1.07 | N/A | 100 |

| Powdered Detergent | >1 | 1.32-1.49 | 80-250 |

| Whey Protein Powder | <1 | 0.41-0.61 | 100-150 |

After doing the research, we found that Whey Protein Powder was the most suitable proxy material to use for our testing. This also had the added benefit of being readily available and relatively inexpensive. We were able to quickly purchase 25kg of protein powder for $100.

Selected Solution

Overview

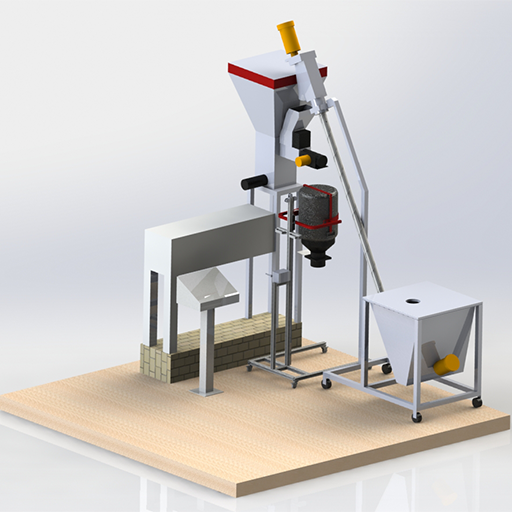

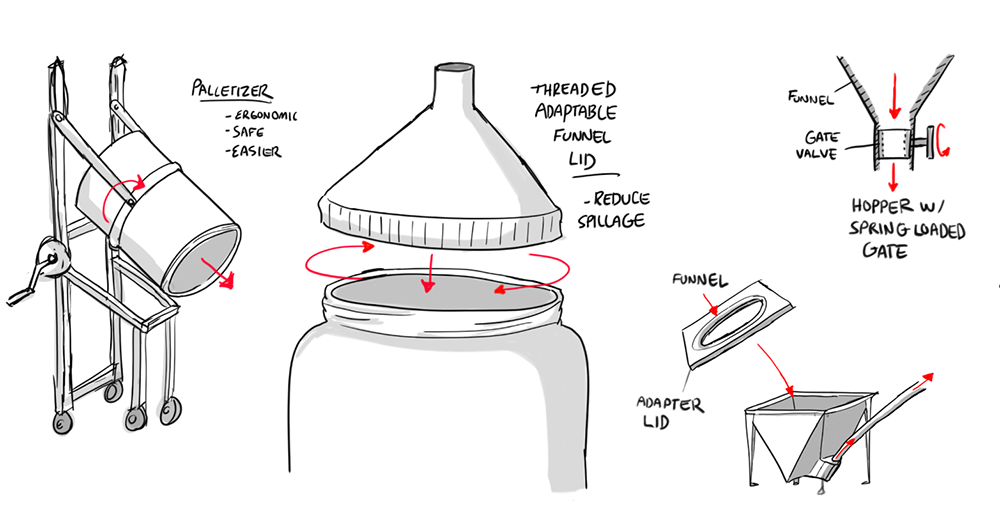

After researching existing solutions to the problem, our team decided on using an industrially available flexible screw conveyor. These systems are common particularly in the food processing industry, are designed and built to industrial quality, and have already been validated. In order to more easily move the yellow powder drums around, and empty them into the base of the screw conveyor, we would design a pail handler / palletizer, which would be built by us in house.

Flexible Screw Conveyor

Early on, it was clear that designing and building an industrial-quality screw conveyor ourselves was out of the question. Instead, we focused on working with manufacturers such as Flexicon and Hapman, seeing which of their products may work for our sponsors. We contacted sales agents at each of these companies, and provided them with the available dimensions and powder properties as measured by QFix. Hapman's quoted system was both less expensive and better suited to QFix's needs, so this is what we recommended to our project sponsors. Hapman's solution consisted of 3 parts:

- The flexible screw conveyor itself, designed to move the powder at the target flowrate ($13,552)

- A fixed-speed control system ($3,074)

- A mobile base so the system could be stored out of the way as needed ($3,411)

The total cost of the screw conveyor system from Hapman came in at $20,037. While this was over the initial budget, the increase in cost was necessary to meet the desired metrics.

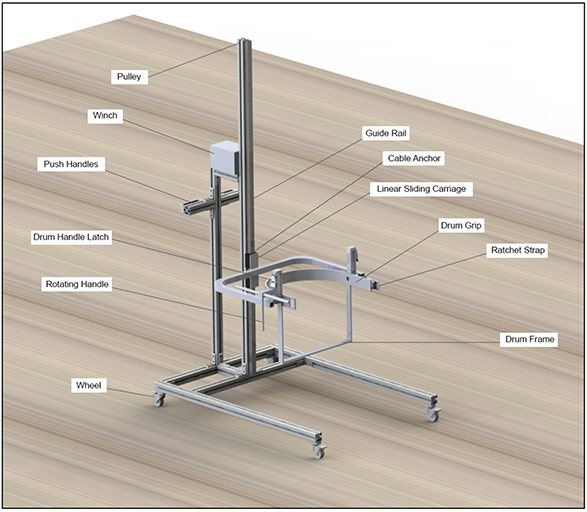

Pail Handler and Lid Adapter

In order to safely move and invert the yellow powder drums, our team designed and built a rolling pail handler. The pail handler was constructed from an aluminum 8020 t-slot extrusion frame. A steel cradle for the drum was welded together. The cradle had buckled straps that locked the drum in place by its built-in handles for inversion, as well as a ratchet strap that would secure the drum laterally. The cradle moved up and down on a steel linear rail, and a winch provided 7:1 mechanical advantage. The cradle was able to sit flat on the floor, meaning the yellow powder drum did not need to be lifted by hand to be loaded. Rubber stoppers prevent the drum from being inverted past 180°.

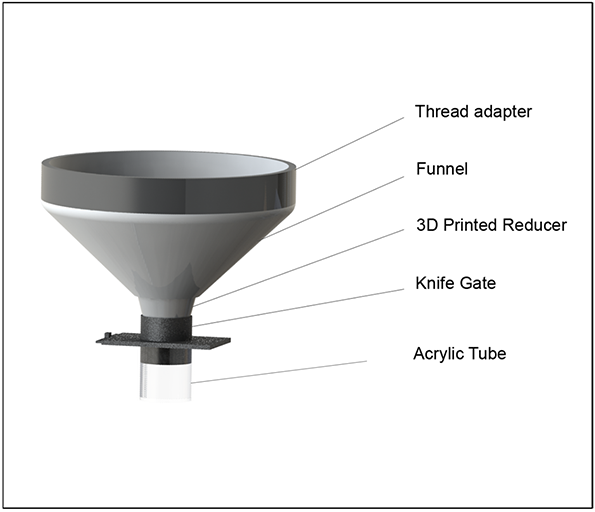

In order to have the yellow powder flow out of the drum and into the base of the flexible screw conveyor without spillage, our team built a lid adapter. This was a funnel with a knife gate, and mated with the drum's threaded mouth. The funnel allowed for more accurate dispensing of the powder, and helped prevent powder from clouding up and drifting away. The knife gate allowed the drum to be inverted wherever convenient, then moved into position and emptied.

Constraint and Want Validation

| Constraint | Target Value | Measured Value | Pass/Fail |

|---|---|---|---|

| Powder availabile in hopper | ≥ 72g at all times | ≥ 72g, specified by Hapman | Pass |

| Ergonomics & Safety | Adhere to OSHA 1910.212 and NIOSH lifting recommendation of < 51lb |

Met OSHA 1910.212 Max lifting force 8lb |

Pass |

| Device Size | Max footprint: 123" x 78" Reach: 8'8" above floor |

Hapman agreed to footprint and reach specifications | Pass |

| System compatibility | System must be able to be retrofitted to existing machinery System must accommodate 25kg powder drum |

No modifications to QFix facility required | Pass |

| Cost | < $15,000 for automated powder transport system < $1,500 for subcomponents. |

$20,037 for screw conveyor $1,000 for pail handler |

Fail |

| Want | Target Value | Measured Value | Pass/Fail |

|---|---|---|---|

| Powder utilization | < 1% of each drum (250g) lost to spillage / dead volume | < 100g lost per drum | Pass |

| Mobility & Ease of Use | Only 1 employee required to operate the loading system | Both pail handler and screw conveyor can be moved by 1 person | Pass |